- Hydraulic Pump

- Hydraulic Pump Parts

- Rexroth Hydraulic Pump Repair

- Hydraulic Piston Pump Repair

- Nachi Hydraulic Pump Repair

- Parker Hydraulic Pump Repair

- Moog Hydraulic Pump Repair

- Daikin Hydraulic Pump Repair

- Denison Hydraulic Pump Repair

- Vicker Hydraulic Pump Repair

- Yuken Hydraulic Pump Repair

- Hydraulic Vane Pump Repair

- kawasaki piston pump repair

- Kawasaki Axial Piston Pumps Repairs

- Eaton piston pump repair

- Sauer Danfoss Piston Pump Repair

- Linde Piston Pump Repair

- Hydraulic Pump Repair

- ATOS Hydraulic Pump Repair

- Kobelco Hydraulic Pump Repair

- Poclain Hydraulic Pump Repair

- Tata Hitachi Hydraulic Pump Repair

- Intermot Hydraulic Motor Repair

- Hydraulic Motor Repair

- Hydraulic Valve Repair

- High Tech Hydraulic Pump Repair

- Hydraulic Pumps Repair All types

- Hydraulic Bent Pump Repair

- Hydraulic Valve

- Hydraulic Motor

- Hydraulic Piston Pump

- BREVINI FLUID POWER Hydraulic Pump Repair

- BREVINI FLUID POWER

- KCL HYDRAULIC PUMP REPAIR

- Schwing Hydraulic Pump

- Adan Hydraulic Motor

- Bucher Hydraulic Pump

- Hagglunds Hydraulic Motor

- Staffa hydraulic Motor Repair

- Kawasaki Piston Pump

- Yuken Hydraulic Motor

- Vickers Hydraulic Vane Pumps

- Eaton Vane Pump Spare Parts

- Tokimec Hydraulic Pump Spare Parts

- Intermot Hydraulic Motor Spare Parts

- Tata Hitachi Hydraulic Pump

- kobelco hydraulic pump Spare Parts

- Kcl Hydraulic Pump Spare Parts

- Liebherr hydraulic pump Spare Parts

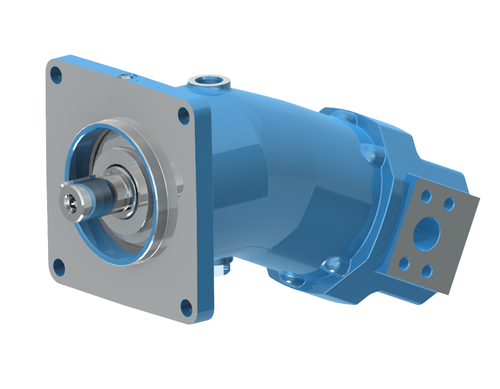

BREVINI FLUID POWER AXIAL PISTON PUMP

Product Details:

BREVINI FLUID POWER AXIAL PISTON PUMP Price And Quantity

- 1 Piece

- 5000 INR/Piece

- Hydraulic Axial Piston

- Designed for long operational life

- Low noise design

- Varies per model; consult datasheet

- Variable (consult manufacturer for options)

- Up to 3000 rpm

- Flange Mounted

- New

- Industrial Hydraulic Applications

- Axial Piston Pump

- Up to 350 bar

- Customizable as per model selection

- Hydraulic

- -20°C to +80°C

- High pressure resistant seals

- Splined or keyed options

- High-Grade Alloy Steel

- BREVINI FLUID POWER AXIAL PISTON PUMP

- Mobile machinery, industrial presses, marine hydraulics, mining equipment

Product Description

Brevini Fluid Power formerly is a leading hydraulic brand. Pump is used in a wide range of industries, including mining and mineral processing, marine, construction and earthmoving, agriculture, renewable energy, general industry and material storage and handling.

High pressure axial piston pumps in bent axis design with fixed displacement suitable for open loop operation and demanding high-performance applications in the mobile and industrial hydraulics. The proven design with 4 ° bent-axis engine, spherical valve plate, high quality components and manufacturing processes enables the use of a continuous pressure up to 430 bar and 480 bar peak loads at speeds up to 3750 rev / min.High efficiency and long life. Large permissible axial and radial forces of the drive shaft due to generously dimensioned bearing. Very compact dimensions

Engineered for Durability and Performance

The BREVINI FLUID POWER AXIAL PISTON PUMP is crafted from high-grade alloy steel, offering resilience in harsh industrial environments. Its design emphasizes longevity, delivering reduced maintenance needs and reliable operation even under continuous high-pressure workloads. This makes it ideal for critical applications in mining, marine, and heavy machinery industries.

Versatile Applications Across Industries

Adaptable and customizable, this hydraulic pump finds its place in a wide range of sectors. It efficiently powers hydraulic circuits in mobile construction machinery, enhances productivity in industrial presses, and performs reliably in marine and mining sectors. Variable displacement options cater to specific requirements, ensuring seamless integration.

FAQs of BREVINI FLUID POWER AXIAL PISTON PUMP:

Q: How do I determine the appropriate model of BREVINI FLUID POWER AXIAL PISTON PUMP for my application?

A: To select the right pump model, assess your desired flow rate, operating pressure, rotational speed, and specific application parameters. Consult the product datasheet or contact the manufacturer for guidance on customization and model compatibility with your system.Q: What are the benefits of using high-pressure resistant seals in this pump?

A: High-pressure resistant seals minimize leakage and enhance the pumps operational reliability, particularly under demanding conditions. This feature contributes to a longer service life and lower maintenance costs.Q: When should the pump be serviced to maintain peak performance?

A: Regular maintenance intervals vary based on the application and operating conditions, but it is recommended to perform inspections based on the manufacturers guidelines. Monitor for changes in noise levels, performance, or visible wear to determine service needs.Q: Where can I find the port size and displacement options for each model?

A: Port sizes and displacement specifications differ by model. Refer to the official product datasheet or consult with the supplier to obtain accurate details tailored to your requirements.Q: What is the process for mounting the pump onto existing machinery?

A: The pump is flange-mounted, simplifying installation onto compatible hydraulic systems. Ensure proper alignment of the input shaft (splined or keyed) and secure fittings according to installation instructions provided by the manufacturer.Q: How does the low noise design benefit industrial operations?

A: The low noise design minimizes sound emissions, creating a safer and more comfortable work environment. This is particularly beneficial in indoor settings or applications where noise reduction is essential for compliance or operational efficiency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

|

REXO HYDRAULIC PUMPS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese