x

- Hydraulic Pump

- Hydraulic Pump Parts

- Rexroth Hydraulic Pump Repair

- Hydraulic Piston Pump Repair

- Nachi Hydraulic Pump Repair

- Parker Hydraulic Pump Repair

- Moog Hydraulic Pump Repair

- Daikin Hydraulic Pump Repair

- Denison Hydraulic Pump Repair

- Vicker Hydraulic Pump Repair

- Yuken Hydraulic Pump Repair

- Hydraulic Vane Pump Repair

- kawasaki piston pump repair

- Kawasaki Axial Piston Pumps Repairs

- Eaton piston pump repair

- Sauer Danfoss Piston Pump Repair

- Linde Piston Pump Repair

- Hydraulic Pump Repair

- ATOS Hydraulic Pump Repair

- Kobelco Hydraulic Pump Repair

- Poclain Hydraulic Pump Repair

- Tata Hitachi Hydraulic Pump Repair

- Intermot Hydraulic Motor Repair

- Hydraulic Motor Repair

- Hydraulic Valve Repair

- High Tech Hydraulic Pump Repair

- Hydraulic Pumps Repair All types

- Hydraulic Bent Pump Repair

- Hydraulic Valve

- Hydraulic Motor

- Hydraulic Piston Pump

- BREVINI FLUID POWER Hydraulic Pump Repair

- BREVINI FLUID POWER

- KCL HYDRAULIC PUMP REPAIR

- Schwing Hydraulic Pump

- Adan Hydraulic Motor

- Bucher Hydraulic Pump

- Hagglunds Hydraulic Motor

- Staffa hydraulic Motor Repair

- Kawasaki Piston Pump

- Yuken Hydraulic Motor

- Vickers Hydraulic Vane Pumps

- Eaton Vane Pump Spare Parts

- Tokimec Hydraulic Pump Spare Parts

- Intermot Hydraulic Motor Spare Parts

- Tata Hitachi Hydraulic Pump

- kobelco hydraulic pump Spare Parts

- Kcl Hydraulic Pump Spare Parts

- Liebherr hydraulic pump Spare Parts

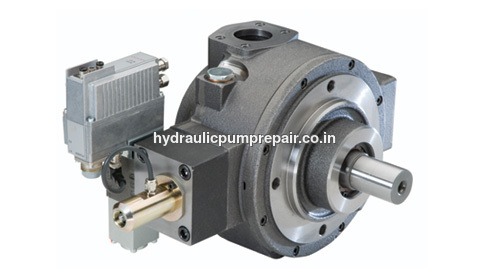

Moog hydraulic motor repair

5000 INR/Unit

Product Details:

X

Moog hydraulic motor repair Price And Quantity

- 5000 INR/Unit

- 1 Unit

- OEM Standard Procedures

- Moog Hydraulic Motors

- Industrial

- Hydraulic

- Repair

- Anti-corrosion Coating

- Yes, available

- Hydraulic Motor Repair

- Performance Bench-Tested

- Certified Hydraulic Technicians

- Standard O.E.M. parts

Moog hydraulic motor repair Trade Information

- 150 Unit Per Day

- 1 Week

- All India

Product Description

We are the major enterprise in the market that is involved in providing a spectacular radius of Moog Hydraulic Motor Repair Services. They help customers by avoiding motors downtime by offering timely and fast repairing of the hydraulic motors. Our personnels have years of experience in the motor repair industry and ensures the addition of more functional working years to clients devices. The services are rendered at an economical price along using the high-tech devices. The Moog Hydraulic Motor Repair Services are extremely dependable.Expert Moog Hydraulic Motor Repairs

Benefit from professional repair services for Moog hydraulic motors, executed by certified technicians using OEM standard procedures and original parts. Each motor is restored for peak performance, undergoing stringent testing and advanced treatments to withstand industrial conditions. Tailored solutions ensure compatibility, reliability, and extended operational life.

Stringent Quality Assurance and Testing

Every repaired Moog hydraulic motor is performance bench-tested to verify functionality and durability. Advanced anti-corrosion coatings are applied to protect surfaces in harsh industrial environments. This comprehensive approach ensures that motors are safe, reliable, and deliver consistent results post-repair.

FAQs of Moog hydraulic motor repair:

Q: How is a Moog hydraulic motor repaired using OEM standard procedures?

A: Our technicians follow official OEM-standard procedures throughout the repair process, utilizing only genuine Moog parts and specialized tools. This maintains manufacturer integrity and ensures optimal motor performance after repair.Q: What types of Moog hydraulic motors can you service?

A: We repair all models of Moog hydraulic motors used in industrial applications, guaranteeing full compatibility and reliable functionality for each unit we handle.Q: When should I consider repairing my Moog hydraulic motor instead of replacing it?

A: Motor repair is recommended when performance declines due to wear or component failure. Opting for OEM-standard repair can restore efficiency and extend motor life at a lower cost compared to full replacement.Q: Where are your Moog hydraulic motor repair services available in India?

A: Our repair services are offered throughout India, serving clients in industrial sectors as an exporter, service provider, supplier, and trader. We cater to both domestic and international industries requiring Moog motor repairs.Q: What is the testing process after hydraulic motor repair?

A: After repair, motors undergo rigorous performance bench-testing. This ensures operational stability, verifies repairs, and checks conformity to Moog specifications before returning the motor to service.Q: How does the anti-corrosion surface treatment benefit my hydraulic motor?

A: The anti-corrosion coating applied after repair protects your motor against rust and environmental damage, thereby enhancing its durability and minimizing maintenance needs in demanding industrial settings.Q: What after-sales support do you provide for repaired Moog hydraulic motors?

A: We offer comprehensive after-sales service, assisting clients with operational guidance, troubleshooting, and ongoing maintenance to ensure the long-term reliability and optimal performance of their motors.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Moog Hydraulic Pump Repair' category

|

REXO HYDRAULIC PUMPS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese