x

- Hydraulic Pump

- Hydraulic Pump Parts

- Rexroth Hydraulic Pump Repair

- Hydraulic Piston Pump Repair

- Nachi Hydraulic Pump Repair

- Parker Hydraulic Pump Repair

- Moog Hydraulic Pump Repair

- Daikin Hydraulic Pump Repair

- Denison Hydraulic Pump Repair

- Vicker Hydraulic Pump Repair

- Yuken Hydraulic Pump Repair

- Hydraulic Vane Pump Repair

- kawasaki piston pump repair

- Kawasaki Axial Piston Pumps Repairs

- Eaton piston pump repair

- Sauer Danfoss Piston Pump Repair

- Linde Piston Pump Repair

- Hydraulic Pump Repair

- ATOS Hydraulic Pump Repair

- Kobelco Hydraulic Pump Repair

- Poclain Hydraulic Pump Repair

- Tata Hitachi Hydraulic Pump Repair

- Intermot Hydraulic Motor Repair

- Hydraulic Motor Repair

- Hydraulic Valve Repair

- High Tech Hydraulic Pump Repair

- Hydraulic Pumps Repair All types

- Hydraulic Bent Pump Repair

- Hydraulic Valve

- Hydraulic Motor

- Hydraulic Piston Pump

- BREVINI FLUID POWER Hydraulic Pump Repair

- BREVINI FLUID POWER

- KCL HYDRAULIC PUMP REPAIR

- Schwing Hydraulic Pump

- Adan Hydraulic Motor

- Bucher Hydraulic Pump

- Hagglunds Hydraulic Motor

- Staffa hydraulic Motor Repair

- Kawasaki Piston Pump

- Yuken Hydraulic Motor

- Vickers Hydraulic Vane Pumps

- Eaton Vane Pump Spare Parts

- Tokimec Hydraulic Pump Spare Parts

- Intermot Hydraulic Motor Spare Parts

- Tata Hitachi Hydraulic Pump

- kobelco hydraulic pump Spare Parts

- Kcl Hydraulic Pump Spare Parts

- Liebherr hydraulic pump Spare Parts

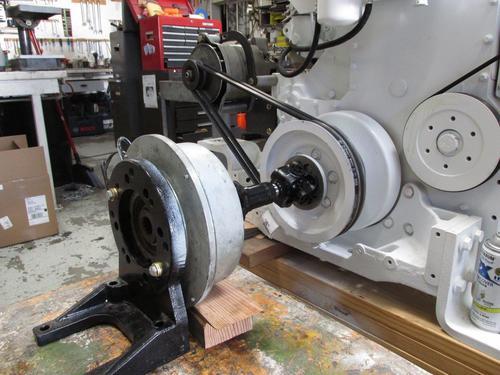

Hydraulic Pump Flanges & Put On Plates

4500 INR/Piece

Product Details:

- Size Available in different sizes (standard and customized as per requirements)

- Shape Round, Rectangular, Customized

- Part Type Pump Flange & Put On Plate

- Material Mild Steel, Stainless Steel, Carbon Steel, or as per specification

- Usage For hydraulic pumps and connections

- Application Used in hydraulic systems, hydraulic pumps, power packs, industrial and mobile hydraulics

- Theory Hydraulic Pressure Transmission

- Click to view more

X

Hydraulic Pump Flanges & Put On Plates Price And Quantity

- 1 Piece

- 2000.00 - 20000.00 INR/Piece

- 4500 INR/Piece

Hydraulic Pump Flanges & Put On Plates Product Specifications

- Hydraulic Pressure Transmission

- Pump Flange & Put On Plate

- Round, Rectangular, Customized

- For hydraulic pumps and connections

- Used in hydraulic systems, hydraulic pumps, power packs, industrial and mobile hydraulics

- Available in different sizes (standard and customized as per requirements)

- Mild Steel, Stainless Steel, Carbon Steel, or as per specification

Hydraulic Pump Flanges & Put On Plates Trade Information

- 50000 Piece Per Day

- 1 Week

Product Description

We have achieved extreme appreciation in the national market for proposing our clients with an enormous range of Hydraulic Pump Flanges & Put On Plates. They are the fittings that help in creating a system be effectively connecting pipes, hoses and tubes and allow the hydraulic liquid to flow without any leaking. The products are the tough mechanical devices which gives amazing functioning throughout their entire lifetime. The Hydraulic Pump Flanges & Put On Plates are accessible in multiple features to best suit the demands of every customer.Versatile and Durable Design

Our pump flanges and put on plates suit diverse hydraulic setups. Crafted with precise machining, they assure seamless integration into your system. Finished with corrosion-resistant coatings, these products endure harsh working environments, minimizing maintenance and maximizing service life.

Optimal Performance for Every Application

These hydraulic components are suitable for industrial, mobile, and power pack hydraulic systems. With a temperature range from -20C to 120C and pressure ratings for medium to high-pressure applications, they perform reliably under demanding conditions while conforming to global standards.

Tailored Solutions for Exact Requirements

Choose from various connection types, mounting options, and packaging styles. Whether you need standard sizes or custom designs, our flanges and plates are manufactured to stringent tolerances, ensuring compatibility and a precise fit for all client specifications.

FAQs of Hydraulic Pump Flanges & Put On Plates:

Q: How do I select the right pump flange or put on plate for my hydraulic system?

A: Assess your systems pressure rating, temperature range, and connection type (threaded, SAE, or custom). Consider material preferences like mild steel or stainless steel, surface finishing requirements, and confirm compatibility with ISO or SAE standards for optimal performance.Q: What surface finish options are available for corrosion resistance?

A: We offer zinc plating, powder coating, painting, and custom finishes to maximize corrosion resistance. Choice of finish depends on environmental conditions and application needs, ensuring longevity even in harsh operating environments.Q: When should I use a bolt-on versus a put-on mounting type?

A: Bolt-on flanges offer secure attachment and are preferred in high-pressure or vibration-prone applications, whereas put-on types are suitable for easier installation and removal in less demanding settings. Selection depends on your installation requirements and hydraulic system configuration.Q: Where can these pump flanges and put on plates be applied?

A: They are widely used in hydraulic pumps, mobile and industrial hydraulic systems, power packs, and other fluid transmission setups. Their robust design allows for versatile application in multiple industries.Q: What is the manufacturing process for these components?

A: Each flange and plate is precision-machined to achieve accurate dimensions and tolerances. After machining, a chosen surface finish is applied to enhance corrosion resistance. All items undergo quality inspections to ensure compliance with ISO, SAE, or specific client standards.Q: How does the high corrosion resistance benefit my system?

A: Enhanced corrosion resistance ensures a longer lifespan for the components, reduces maintenance frequency, and prevents system failures due to environmental degradation, ultimately optimizing operational efficiency.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Hydraulic Pump Parts ' category

|

REXO HYDRAULIC PUMPS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese