x

- Hydraulic Pump

- Hydraulic Pump Parts

- Rexroth Hydraulic Pump Repair

- Hydraulic Piston Pump Repair

- Nachi Hydraulic Pump Repair

- Parker Hydraulic Pump Repair

- Moog Hydraulic Pump Repair

- Daikin Hydraulic Pump Repair

- Denison Hydraulic Pump Repair

- Vicker Hydraulic Pump Repair

- Yuken Hydraulic Pump Repair

- Hydraulic Vane Pump Repair

- kawasaki piston pump repair

- Kawasaki Axial Piston Pumps Repairs

- Eaton piston pump repair

- Sauer Danfoss Piston Pump Repair

- Linde Piston Pump Repair

- Hydraulic Pump Repair

- ATOS Hydraulic Pump Repair

- Kobelco Hydraulic Pump Repair

- Poclain Hydraulic Pump Repair

- Tata Hitachi Hydraulic Pump Repair

- Intermot Hydraulic Motor Repair

- Hydraulic Motor Repair

- Hydraulic Valve Repair

- High Tech Hydraulic Pump Repair

- Hydraulic Pumps Repair All types

- Hydraulic Bent Pump Repair

- Hydraulic Valve

- Hydraulic Motor

- Hydraulic Piston Pump

- BREVINI FLUID POWER Hydraulic Pump Repair

- BREVINI FLUID POWER

- KCL HYDRAULIC PUMP REPAIR

- Schwing Hydraulic Pump

- Adan Hydraulic Motor

- Bucher Hydraulic Pump

- Hagglunds Hydraulic Motor

- Staffa hydraulic Motor Repair

- Kawasaki Piston Pump

- Yuken Hydraulic Motor

- Vickers Hydraulic Vane Pumps

- Eaton Vane Pump Spare Parts

- Tokimec Hydraulic Pump Spare Parts

- Intermot Hydraulic Motor Spare Parts

- Tata Hitachi Hydraulic Pump

- kobelco hydraulic pump Spare Parts

- Kcl Hydraulic Pump Spare Parts

- Liebherr hydraulic pump Spare Parts

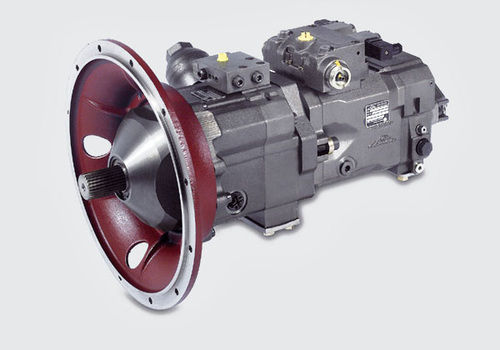

Linde Hydraulic Motor Repair

5000 INR/Unit

Product Details:

X

Linde Hydraulic Motor Repair Price And Quantity

- 1 Unit

- 5000 INR/Unit

- Repair

- Performance and Leakage Testing After Repair

- Service Tailored to Model Requirements

- Technical Assistance Available

- High Torque Capability

- Up to 450 bar

- Industrial Machinery, Construction Equipment, Agricultural Equipment

- Linde Hydraulic Motors and Pumps

- Hydraulic

- Inspection, Overhaul, Replacement of Wear Parts, Testing

- OEM Standards

Linde Hydraulic Motor Repair Trade Information

- 150 Unit Per Day

- 1 Week

- All India

Product Description

Linde hydraulic motor repairs are best quality rotary actuator services, which have been designed to change the hydraulic, or fluid energy into the mechanical power. They work well in tandem with the hydraulic pump. Also, they have the capacity to convert the mechanical power into fluid as well as hydraulic power. Linde hydraulic motor repairs solutions are needed to supply the motion so as to enable an excellent external load. The said solutions are demanded in many industrial applications such as augers, mixers and conveyors. In addition, they have robust nature as well as advanced resistance to heat.Comprehensive Inspection and Overhaul

Each Linde hydraulic motor undergoes a meticulous inspection and overhaul process, ensuring all components are assessed for wear and functionality. Our skilled technicians replace damaged or worn parts using OEM-standard components, promising restored performance, reliability, and long-term operational efficiency for demanding industrial, construction, or agricultural applications.

Performance and Leakage Testing

Following every repair, motors are subjected to rigorous performance and leakage testing. This ensures that repaired motors not only meet but exceed operational expectations under high-pressure conditions, safeguarding against unexpected downtime and optimizing durability.

Customized Solutions for Every Model

We recognize that every hydraulic system has unique requirements. Our repair services are customized to your motors specific model and operating environment, offering tailored support whether you are involved in heavy industry, agriculture, or construction.

FAQs of Linde Hydraulic Motor Repair:

Q: How do you ensure repaired Linde hydraulic motors comply with OEM standards?

A: All repairs and replacements are performed using genuine or OEM-equivalent components. Our technicians follow factory-recommended procedures for inspection, overhaul, and testing, guaranteeing performance and reliability consistent with Lindes manufacturing benchmarks.Q: What is the process involved in hydraulic motor repair?

A: Our process includes thorough inspection, diagnosis, cleaning, replacement of worn or faulty parts, reassembly, and rigorous performance and leakage testing. After repair, motors are validated to ensure full operational capability before return.Q: When is it necessary to seek hydraulic motor repair services?

A: Repair is recommended whenever you notice reduced performance, abnormal noises, leakage, or increased energy consumption in your hydraulic motor. Early intervention prevents major failures and extends equipment lifespan.Q: Where can your Linde hydraulic motor repair service be availed in India?

A: Our repair services are available throughout India. We support industrial clients, agricultural operators, and construction firms nationwide through our exporter, supplier, and trading network.Q: What types of equipment and applications are covered by your repair service?

A: We service hydraulic motors in industrial machinery, construction equipment, and agricultural equipment, optimized for applications requiring robust high-torque and high-pressure operation.Q: What testing measures are performed after motor repairs?

A: Every repaired motor undergoes strict performance and leakage tests under simulated working conditions, ensuring that all serviced motors meet operational specifications for pressure and torque.Q: What are the benefits of choosing your hydraulic motor repair service?

A: Clients benefit from extended equipment life, reduced downtime, expert technical support, OEM-compliant quality, and solutions tailored to their specific model and operational needs.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Linde Piston Pump Repair ' category

|

REXO HYDRAULIC PUMPS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese