x

- Hydraulic Pump

- Hydraulic Pump Parts

- Rexroth Hydraulic Pump Repair

- Hydraulic Piston Pump Repair

- Nachi Hydraulic Pump Repair

- Parker Hydraulic Pump Repair

- Moog Hydraulic Pump Repair

- Daikin Hydraulic Pump Repair

- Denison Hydraulic Pump Repair

- Vicker Hydraulic Pump Repair

- Yuken Hydraulic Pump Repair

- Hydraulic Vane Pump Repair

- kawasaki piston pump repair

- Kawasaki Axial Piston Pumps Repairs

- Eaton piston pump repair

- Sauer Danfoss Piston Pump Repair

- Linde Piston Pump Repair

- Hydraulic Pump Repair

- ATOS Hydraulic Pump Repair

- Kobelco Hydraulic Pump Repair

- Poclain Hydraulic Pump Repair

- Tata Hitachi Hydraulic Pump Repair

- Intermot Hydraulic Motor Repair

- Hydraulic Motor Repair

- Hydraulic Valve Repair

- High Tech Hydraulic Pump Repair

- Hydraulic Pumps Repair All types

- Hydraulic Bent Pump Repair

- Hydraulic Valve

- Hydraulic Motor

- Hydraulic Piston Pump

- BREVINI FLUID POWER Hydraulic Pump Repair

- BREVINI FLUID POWER

- KCL HYDRAULIC PUMP REPAIR

- Schwing Hydraulic Pump

- Adan Hydraulic Motor

- Bucher Hydraulic Pump

- Hagglunds Hydraulic Motor

- Staffa hydraulic Motor Repair

- Kawasaki Piston Pump

- Yuken Hydraulic Motor

- Vickers Hydraulic Vane Pumps

- Eaton Vane Pump Spare Parts

- Tokimec Hydraulic Pump Spare Parts

- Intermot Hydraulic Motor Spare Parts

- Tata Hitachi Hydraulic Pump

- kobelco hydraulic pump Spare Parts

- Kcl Hydraulic Pump Spare Parts

- Liebherr hydraulic pump Spare Parts

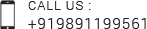

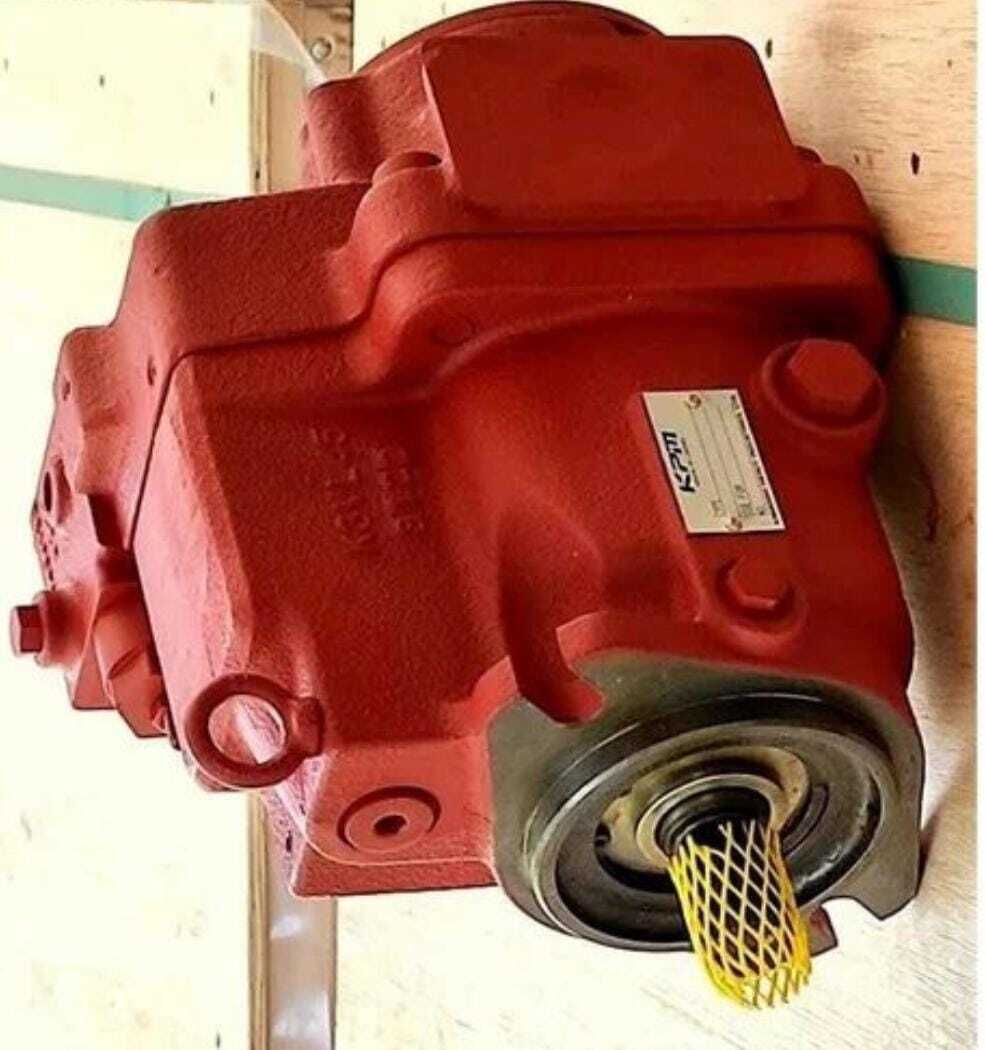

Kawasaki Piston Pump

5500.00 INR/Piece

Product Details:

- Max Suction Up to 6 m

- Control System Pressure Compensator / Manual / Electronic

- Working Temperature -20C to +90C

- Speed Up to 2800 rpm

- Head Size Up to 320 bar

- Noise Level Low Noise Operation

- Mounting Type Flange Mount / Foot Mount

- Click to view more

X

Kawasaki Piston Pump Price And Quantity

- 5500.00 INR/Piece

- 1 Piece

- Customizable

- Horizontal

- Field Repairable

- Keyed / Spline Shaft

- Available

- Standard Grey / Blue Coating

- Clockwise / Counterclockwise

- K3V/K5V/K7V (Various)

Kawasaki Piston Pump Product Specifications

- Up to 2800 rpm

- Industrial / Mobile Equipment

- Up to 130 cc/rev

- Pressure Compensator / Manual / Electronic

- -20C to +90C

- Up to 320 bar

- Low Noise Operation

- Hydraulic Driven

- Cast Iron / Steel

- Up to 6 m

- Hydraulic Oil

- Kawasaki Factory Standard

- Self-priming

- Axial Piston Pump

- High Efficiency, Compact Design, Durable, Reliable

- Threaded/Flanged Ports

- High-Pressure NBR/Viton Seals

- Customized

- 10 to 130 L/min

- Positive

- Up to 320 bar

- Variable / Fixed Displacement Piston Pump

- Up to 320 bar

- Excavators, Loaders, Construction Machinery

- Flange Mount / Foot Mount

- Axial Piston Type

- Customizable

- Horizontal

- Field Repairable

- Keyed / Spline Shaft

- Available

- Standard Grey / Blue Coating

- Clockwise / Counterclockwise

- K3V/K5V/K7V (Various)

Kawasaki Piston Pump Trade Information

- 5500 Piece Per Day

- 1 Week

Product Description

kawasaki Hydraulic Piston Pump for it is used for hydrostatic drives in open circuit hydraulic system. Designed for use in mobile applications.It operates under self-priming conditions, with tank pressurization, and with an other built-in charge pump. A comprehensive range of control is available matching any application requirement. Power control option is externally adjustable, even when the pump is running. it normal pressure is 5100psi (350bars) and it maximum pressure is 5800 psi( 400 bars).

Superior Hydraulic Performance

These Kawasaki Piston Pumps are designed to deliver consistent flow and pressure across a wide range of industrial and mobile machinery, including excavators, loaders, and construction equipment. Their robust design ensures stability and efficiency even in challenging environments, making them a top choice for heavy-duty applications.

Customizable and User-Friendly Design

With customizable installation positions and options for keyed or spline shafts, users can adapt the pumps to meet specific system requirements. Additionally, the availability of threaded or flanged ports and multiple mounting types simplifies integration, providing flexibility in diverse hydraulic setups.

Efficient and Reliable Operation

Engineered with advanced pressure compensator, manual or electronic control systems, these pumps guarantee precise performance and low noise levels. High-efficiency axial piston technology and high-pressure seals minimize downtime, while accessible replacement parts and field repairability support sustained productivity over time.

FAQs of Kawasaki Piston Pump:

Q: How can I ensure the correct installation of the Kawasaki Piston Pump in my system?

A: The pump supports customizable installation positions, including flange or foot mounting, and can be oriented horizontally. Choose from keyed or spline drive shafts to match your equipment specifications. Consult with a qualified technician or refer to Kawasakis installation guidelines for best results.Q: What applications are suitable for the K3V/K5V/K7V pump series?

A: These pumps are ideal for use in excavators, loaders, construction machinery, and similar industrial or mobile equipment that require robust, high-pressure hydraulic systems. Their durability and efficiency make them well-suited for demanding operational conditions.Q: When should I consider servicing or replacing parts in the piston pump?

A: Routine maintenance schedules should be established based on operating hours and environment. If you observe reduced performance, abnormal noise, or leaks, inspect the pump and replace worn components using the readily available replacement parts to maintain optimal functionality.Q: Where can I obtain replacement parts or technical support for these pumps?

A: Replacement parts and professional support are available through authorized Kawasaki exporters, suppliers, service providers, and traders in India or your region. Contact your pump provider to ensure you receive genuine parts and expert assistance.Q: What is the process for switching the pumps rotation direction?

A: The pump can operate in both clockwise and counterclockwise directions. To change the rotation, ensure that your drive setup and control system align with the desired direction, and consult the product manual or technical support for the proper procedure.Q: How does using high-pressure NBR/Viton seals benefit my hydraulic system?

A: High-pressure NBR/Viton seals provide excellent resistance to a broad range of hydraulic oils and extreme temperatures, ensuring leak-free operation and extended pump service life, even under demanding working conditions.Q: What advantages does the axial piston pump design offer?

A: Axial piston pumps deliver high efficiency, precise control, and consistent output, especially under variable loads and speeds. The compact and durable construction supports reliable operation with lower noise emissions, supporting long-term productivity.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

|

REXO HYDRAULIC PUMPS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese